2016 Logan County Fall Farm Outlook Magazine

Lincoln Daily News

Oct. 27, 2016

43

Continued ►

About two-thirds of the N in a corn plant ends up in

the grain.

A 200-bushel crop would have about 240 pounds of N

in the plants before harvest.

This is 1.2 pounds N per bushel, the factor used

to convert proven or expected yield into N rate

recommendations

- “1.2 is the most [we] should do.” -

While soil type and condition, which influences the

availability of N, are steady factors in a given field;

there will always be a bit of a gamble as the weather

- rains and temperatures - play a big factor in how

much N is available when a plant needs it most.

Year 1 - University of Illinois 2014 N-Watch field

trials conclude:

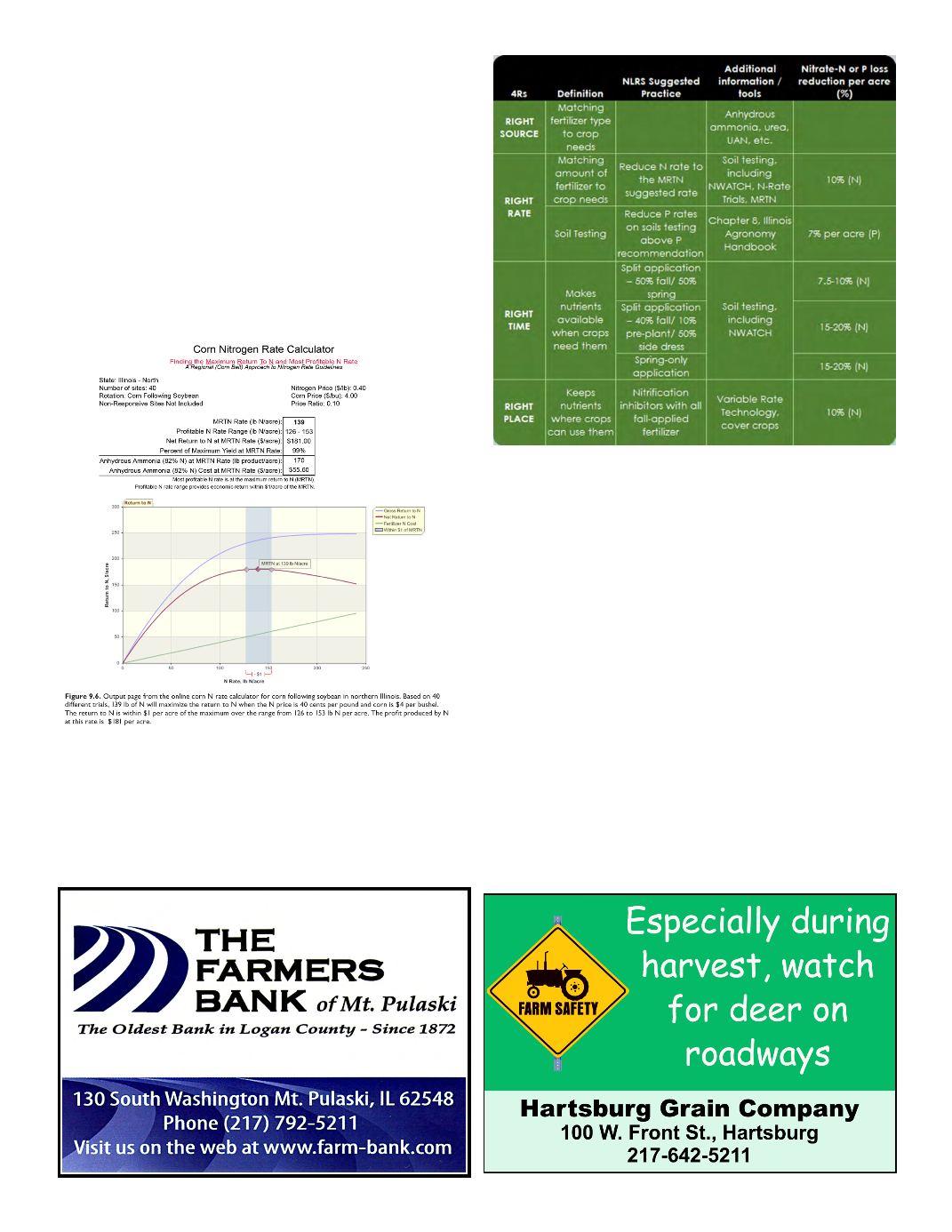

• Getting the “right” N rate, timing, form, and

placement is possible, but the end result is and

will remain inexact – The list of N practices that

belong on (or can’t yet be taken off) the 4R list might

be longer than we might think

• We can’t assume loss of early applied N, (but

should be ready to respond after loss)

• We can’t assume an advantage to late applied N

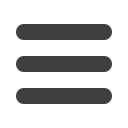

• Common sense says: start with the MRTN rate

and build a “safe” N system – one without big

dangers of deficiency or loss. The newest field

tests and data studies now focus on when yields are

maximized to the cost of applied N (MRTN).